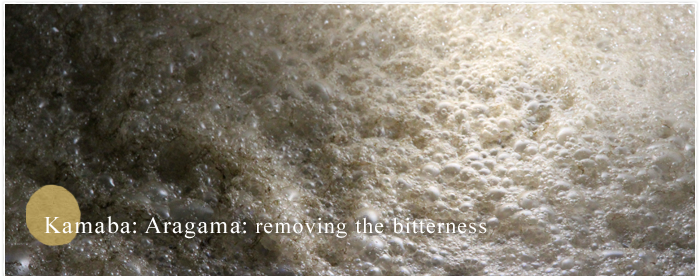

Kamaba(literally means "pot place"): Aragama(first pot): removing the bitterness

In the "kamaba" we boil down the juice extracted from sugar cane. The Kamaba process is divided into several phases. The first phase consists of removing the bitter foam whitch accumulates at the top from the jouice in an Aragama.

As the fresh juice squeezes out of sugar cane contains much lye(mainly from the ears of sugar cane), it has a thick, greenish color. An Aragama is a pot specially made for drawing out this lye.

We pour the juice into the pot until it is about half full, then heat it. Lots of lye comes out as can be seen by the green foam. At this point we carefully scoop it out with a fine net. It is impossible, however, to scoop out all the lye. The Aragama, therefore, has a lid with openings along the edge. By continuing to heat it, the lye accumulates along the edges of the pot. This process is continued by controlling the heat until all the harshness is removed. This process is called "Fukashi(steaming; boiling)".

The above picture shows the procedd of "Fukashi". We have to watch carefully and control the amount of steam so that only the lye is extracted.

This process takes about 30 minutes. Since one person has to attend to one pot duaring the entire process, it is costly in terms of labor and time. If we do not complete this process correctly, however, the finished product turns dark due to the remaining lye. The process of removing the bitter lye foam, therefore, is an important one whitch determines the quality of the finished product.