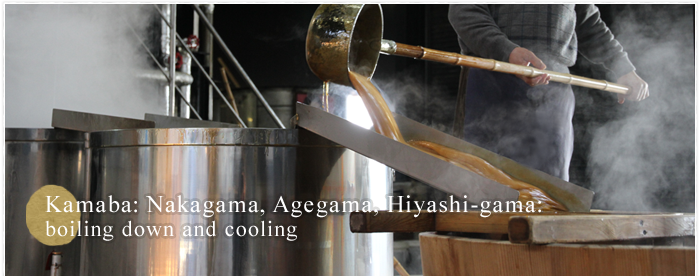

The process of making Awa wasanbon toh---the "kamaba(pot place)" process,"Naka-gama(second pot)","Age-gama(finishing pot)","Hiyashi-gama(cooling pot)"

As we proceed from "Sumashi-oke" to "Naka-gama" and further, to "Age-gama," the clarified sugar cane juice is gradually boiled down to become finished product. "Naka-gama" is simply a condensing pot, and "Age-gama" is, as it literally indicates, a finishing pot. When the juice has been boiled down to the proper consistency, it is moved to "Hiyashi-gama" for cooling.

In spite of the fact that boiling down is the most important part of the process in the "Kamaba", no thermometer nor saccharimeter is used. The only means for judging if the process has been completed are by the way the thickened juice drips from the bamboo stick used for stirring and by the instincts of the boiler. Since this work requires great expertise, the most experienced person is placed in charge. This person is called "Omodaki(chief boiler)".

As squeezing and condensing the juice it is a sort of assembly-line process, the chief boiler controls a day's whole work by consulting with the person in charge of "Shimeba(literally meaning "squeezing place")". In the picture above, the chief boiler appears in the middle. The woman on the left is "Naka-daki," who takes care of the intermediary process of boiling.

In the above picture of "Kamaba", we can see the three stainless steel pots on the left and a wooden pot on the right. The two pots on the left are "Naka-gama"; the one with the chief boiler holding the bamboo stick is an "Age-gama". The wooden pot is a "Hiyashi-gama", a special pot for cooling. No heating function is attached to this cooling pot. Instead, it has a stirring system to cool the condensed juice naturally.

Simply condensing and cooling does not produce sugar; crystalization is necessary. If the juice is cooled too slowly without a Hiyashi-gama, the sugar crystals become too large, resulting in the excess roughness of finished product. On the other hand, if the juice is cooled too rapidly, no crystalization occurs, resulting in syrup, not sugar.

Experience tells us that cooling in a wooden pot while stirring neither too fast nor too slow provides the best cooling results. Wooden pots are used for over 30 years and only require occasional repair.